Introduction to Stacking Racks: A Comprehensive Guide

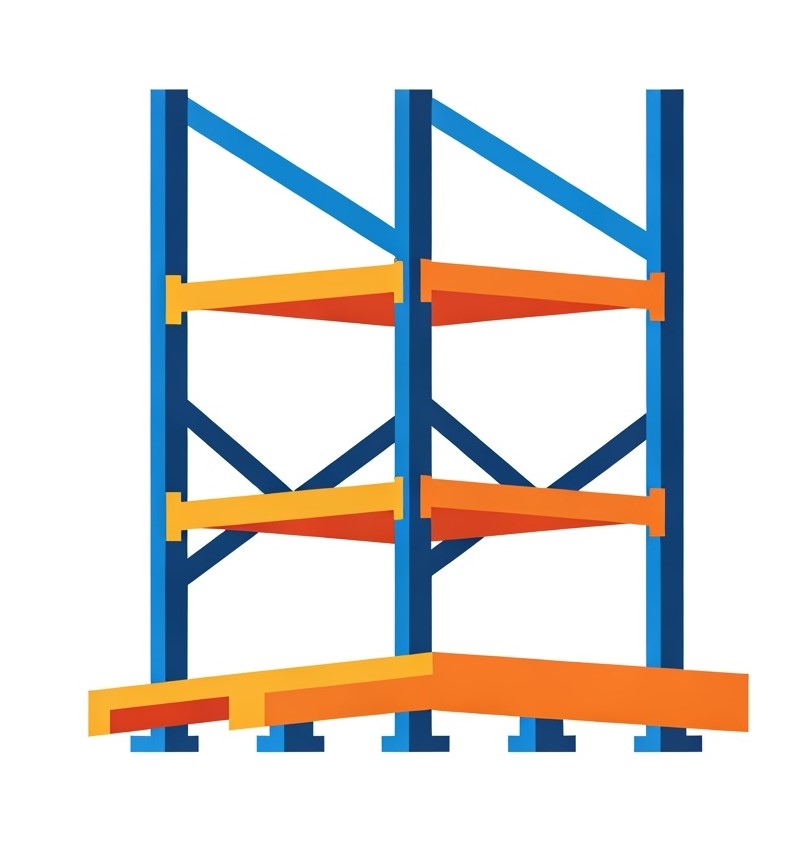

What is a Stacking Rack?

A stacking rack is a type of storage system designed to optimize space utilization by allowing multiple racks to be stacked on top of each other. These racks are commonly used in warehouses, manufacturing plants, and logistics centers to store goods efficiently while maintaining easy accessibility. They are often made of heavy-duty steel and come in various configurations to accommodate different storage needs.

How Stacking Racks Are Made

Stacking racks are typically made from high-quality steel or other durable metals to ensure strength and stability. The manufacturing process involves:

- Material Selection – Using industrial-grade steel for durability.

- Cutting and Welding – Components are cut to size and welded for a strong frame.

- Powder Coating or Galvanization – This provides corrosion resistance and extends the lifespan of the racks.

- Assembly and Quality Control – Final inspections ensure the racks meet safety standards before being distributed.

Usages of Stacking Racks

Stacking racks are used in various industries, including:

- Warehousing & Storage – To store goods in an organized manner.

- Manufacturing – To keep raw materials and finished products secure.

- Retail – For bulk product storage in backrooms.

- Agriculture – Used for storing fruits, vegetables, and other produce.

- Automotive Industry – For storing parts and components securely.

Advantages of Stacking Racks

✔ Space-Saving – Allows vertical stacking, maximizing storage space.

✔ Flexibility – Can be easily reconfigured to suit different storage needs.

✔ Mobility – Some stacking racks are portable, making them ideal for temporary storage solutions.

✔ Durability – Made from strong materials to handle heavy loads.

✔ Easy Handling – Designed for forklift accessibility, improving operational efficiency.

Disadvantages of Stacking Racks

✘ Initial Cost – High-quality stacking racks can be expensive.

✘ Weight Limitations – Overloading can compromise stability and safety.

✘ Assembly Time – Some racks require time and effort to set up.

✘ Space Constraints – Not ideal for very low-ceiling storage areas.

Extra Features and Customization

Many stacking racks can be customized based on industry requirements. Features include:

- Adjustable heights and dimensions

- Collapsible or foldable designs for easy storage when not in use

- Removable posts for flexibility

- Heavy-duty casters for mobility

Contact us (www.China-Racks.com) today: Contact Us to discover how Qingdao Streamline Racks Co., Ltd. can transform your material handling operations and help you achieve your business goals.

We’re ready to partner with you and provide the solutions you need to thrive.